English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

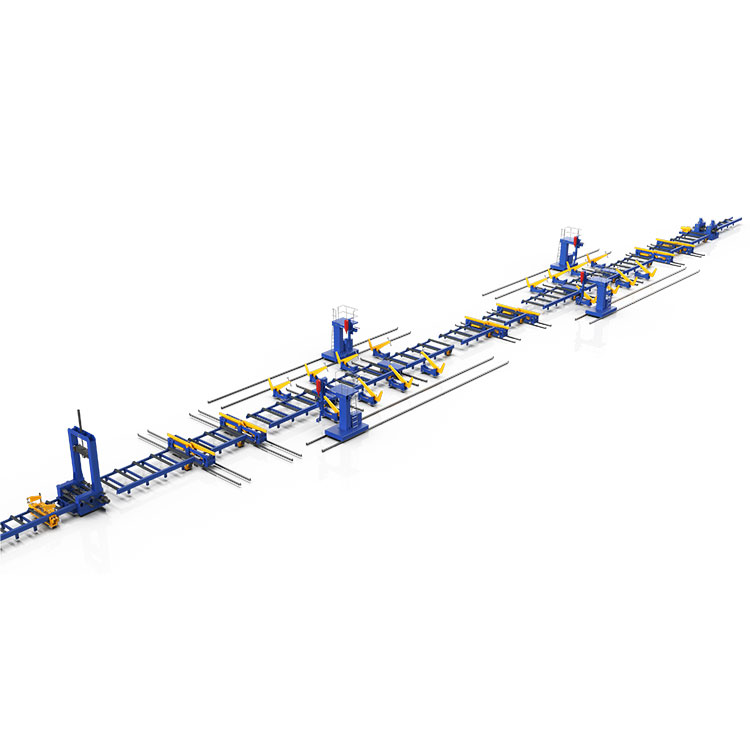

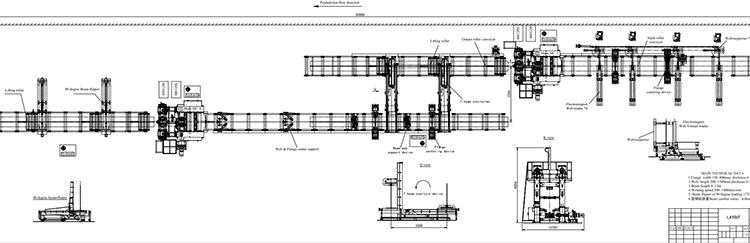

2-1-7 III in I h trabem welding linea

Mitte Inquisitionem

Nam omnis th3-in I h trabem welding lineas quod fabricari byJinfenfg Weldcut erit XII menses warantum, quae sunt summum efficientiam apparatus ad augendam productivity pro fine-users ex ferro structuram, pontem, constructione.

Cubits

|

Exemplar |

Zhj15 |

ZJ18 |

Zhj20 |

|

T-trabem Webeight (H) |

CC ~ 1500mm |

200-1800 |

200-2000mm |

|

Web Crassitudo (D) |

VI ~ 12mm |

VI ~ 19mm |

VI ~ 30mm |

|

Luckewidth (b) |

CC ~ 800mm |

CC ~ 1000mm |

|

|

Flangethickness (T) |

VI ~ 25mm |

VI ~ 40mm |

|

|

Trabem longitudinem (l) |

(IV) ~ 15000mm |

(IV) ~ 15000mm |

(IV) ~ 15000mm |

|

Trabem materiales |

Q235 |

||

|

Welding Type |

Submerged arcum transversum fillet Welding |

||

|

Welding Power Source |

Single filum aut geminae filum type |

Unum filum |

Unum filum |

|

Welding output celeritate |

CC ~ M mm / min |

||

|

ADCUCO: |

Die XLV Description |

||

|

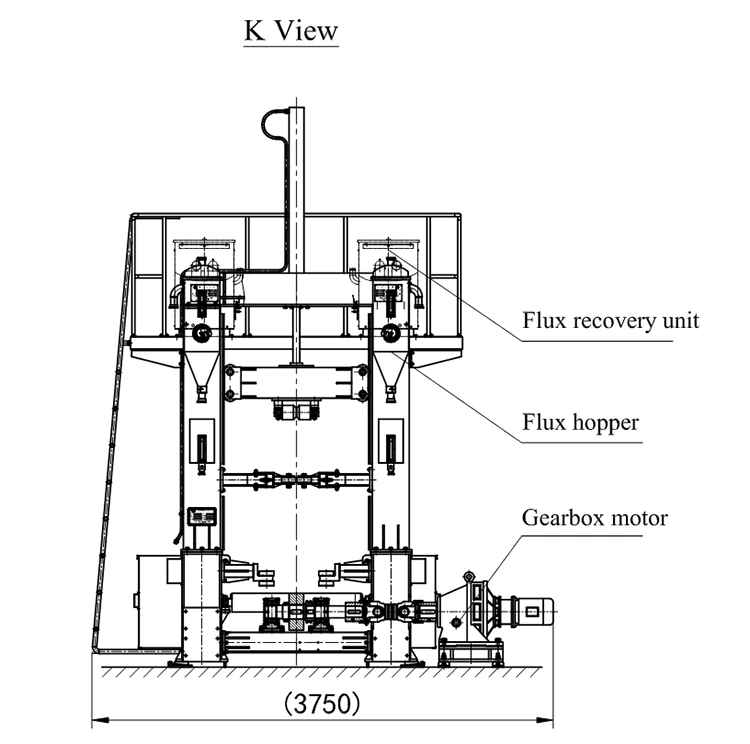

HYDRAULICUS |

≤14 MPA |

||

|

Pandora Recuperatio System |

2Sets |

||

|

Volume de Pandora Hopper |

II × 50l |

||

|

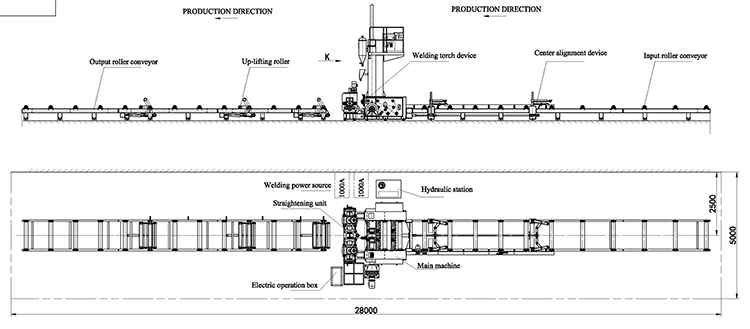

Input TRADUCTOR Roller: |

(XII) mm |

||

|

Output TRADUCTOR Roller: |

(XII) mm |

||

|

Main Machina Power |

18.0KW |

||

|

HYDRAULICUS System: |

1set |

||

|

Erigens |

I set, integrated in apparatus |

||

|

Vox copia: |

AC / CCCLXXX V / L HZ / 3ph |

||

|

Erigens |

6-40mm |

||

Pluma et applicationem

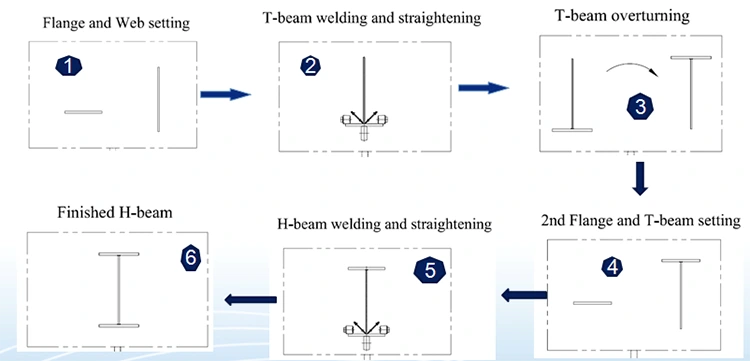

III, in I h trabem welding lineae habet ut combined munus h trabem, T, trabem ecclesiam, welding et flange deformatio erigens post welding. Et sic potest verius et cursim animadverto H trabem et T trabem production.it habet sequenti commoda: simplex operatio, minus labore sumptus et parva operimentum area.

Haec linea habet duas libitum Welding processus pro vobis eligere secundum structural ferro laminam crassitudine ad esse conflatum:

OPTION A: Single arc twin wire welding of which the deposition rate is 40% higher than the general single arc single wire submerged arc welding, Sot it is especially suitable for the structure steel thickness of which the thickness is less than 20mm.

Optio B: unum arcus unum filum welding.it idoneam maior rhoncus de laminam crassitudine welding.

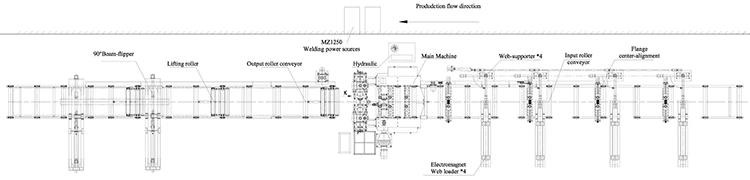

Details

Et vexillum Zhj3-in I h trabem welding linearum consistit ex uno input cylindro mensam, principalis welding et erigens statione, outputroller Table.on Pandora et Righting Station ibi InstalledWith vexillum et Clamping et LABORS et Web.The et Clamping et Welding Power et Welding et Taxi et Clamping et Welding Box.

I. Standardzhj3-in I h trabem welding lineae

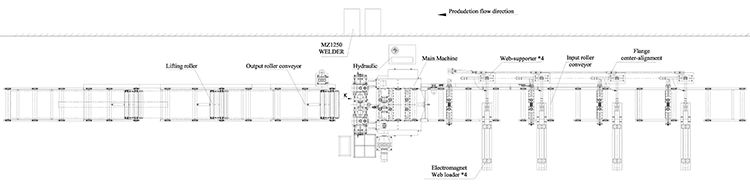

II. Optio I:

Ut per alium petitiones a customers, nos quoque providere configuratione pro thezhj3-in I h trabem welding lineas sicut haec:

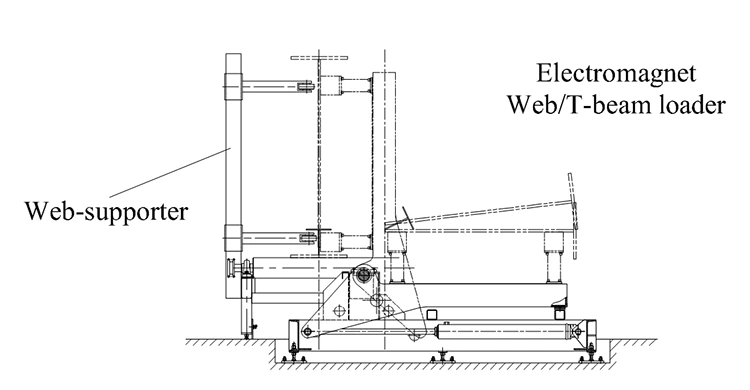

Secundum in Latin III-in-I h trabem welding lineas, ibi addere unum paro of web-loader, whichconsists de IV PCs de Magnet Loading Armate et 4pcs de Magnet et tenens ferro Web.

III. Optio II:

Ut per alium petitiones a customers, nos quoque providere configuratione pro thezhj3-in I h trabem welding lineas sicut haec:

Secundum in Latin III-in-I h trabem welding lineas, ibi addere unum paro of web-loader, whichconsists de IV PCs de Magnet Loading Armate et 4pcs de Magnet et tenens ferro Web.

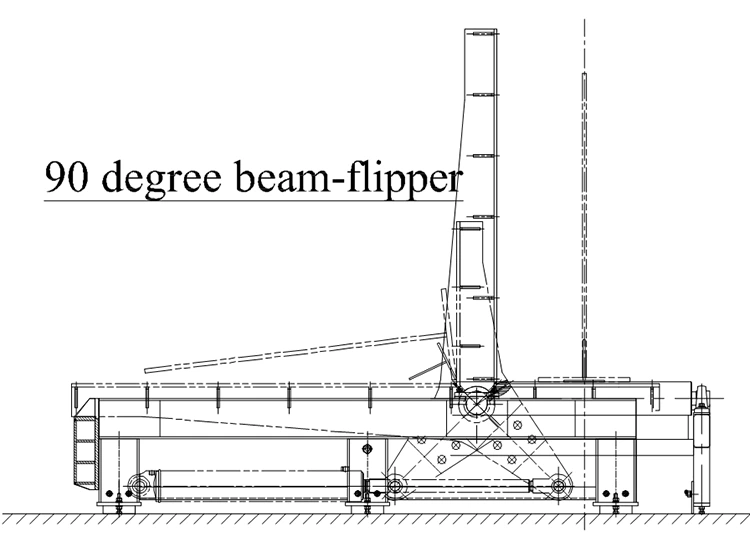

Ex supra, possumus addere unam paro of XC gradus trabulus flipper in output cylinder mensam pro evertere ad solvendum trabem in horizontali positione.

III. Optio III:

Some customers may need to increase theproduction output, they need one welding line to consists of 2 sets of welding station.The first welding station for welding 1st flange and web to form a T beam, the 2nd one for welding the welded T-beam and 2nd flange to form a H beam.

3,1 Sic fundatur in Latin III-in-I h trabem welding lineas, ibi addere unum paro of web-loader et 4pcs de Magnet et Tela Telae Web are 2pcs de Magnet et tenens ferro Web.

3,2 addere I paro of T, trabem subvertit ad conversus in T trabem in CLXXX gradus et ponendo in T-trabem in 2 LABIUM in input cylnge in mensa 2nd welding statione.

3,3 ad unum paro of XC gradus trabper flipper in output cylindro mensa of2nd welding statione pro evertere ad solvendum trabem in horizontali loco.

T trabem et h, trabem productio influunt

III-in-I integrated h, trabem welding lineas installed in users, officinas